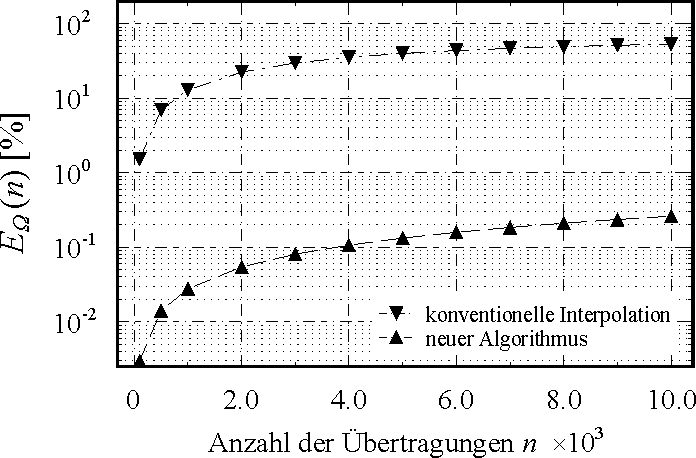

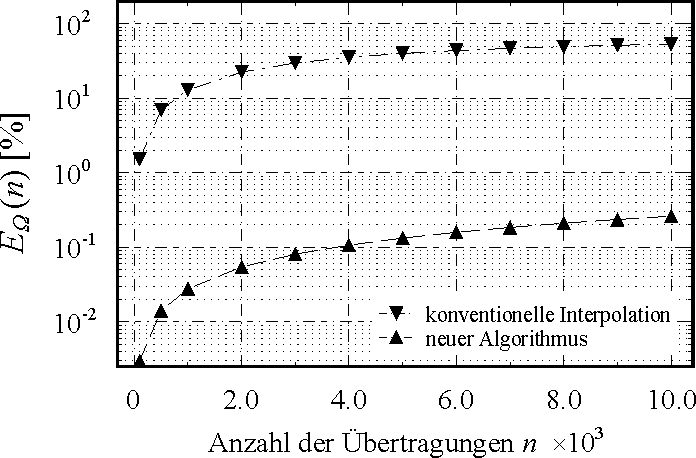

- investigation of the mathematical behavior of the new remap method by the comparison of the accumulated error E after a given number of repetitions n (2)

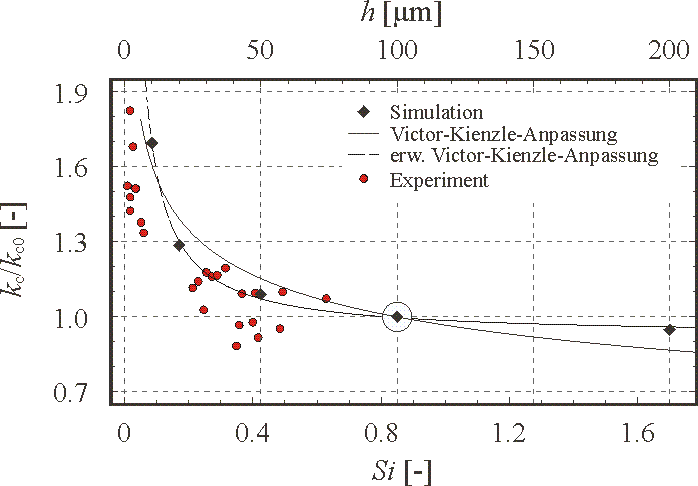

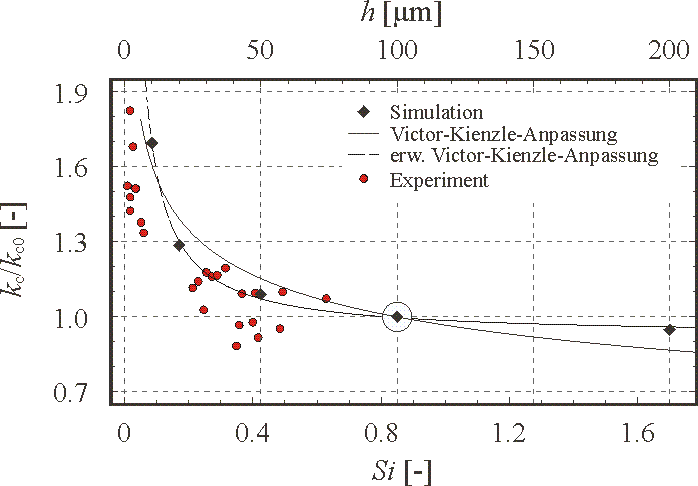

- investigation of the size effect of the specific cutting force and macroscopic evidence of its continuum mechanical causes

- investigation of the local material loading history in the micro machining process for different process parameter sets

|

- the new remap method is well suited to micro machining simulations since its mathematical diffusion is more than two orders lower than it is for an interpolation (Fig. 2)

- the size effect of the specific cutting force is primarily caused by the strain rate sensitivity of AISI-1045 (Fig. 3)

- large cutting edge radii in micro machining (see Fig. 1) lead to a cyclic plastic deformation near the work piece surface

|