| Person in Charge: M. Sc. Claudia Grau |

|

Motivation and objectives:

Induction surface hardening is an energy-efficient and low distortion alternative to case hardening.

Due to the flexibility of dual frequency induction hardening the microstructure of diverse gear wheels areas can be adjusted selective and location-independent and so is it possible to customise the microstructure to the local alternating loading. By optimal process control an improvement of the surface layer properties of induction hardened gear wheels compared to the surface layer properties of case hardened gear wheels should be achieved. |

|

| Methods |

Results |

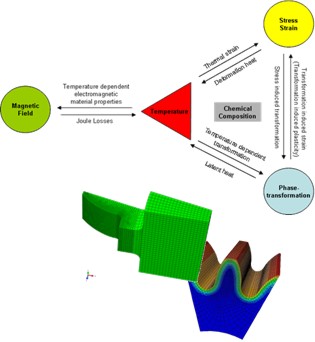

- Extension of the 3D model of dual frequency induction surface hardening with respect to material properties

- Determination of the limitations of the process via variation of the process variables

- Adjustment of optimal surface structure of gear wheels by dual frequency induction surface hardening

- Comparision of fatigue life of induction hardened and case hardened gear wheels

|

|

|