Research

|

|

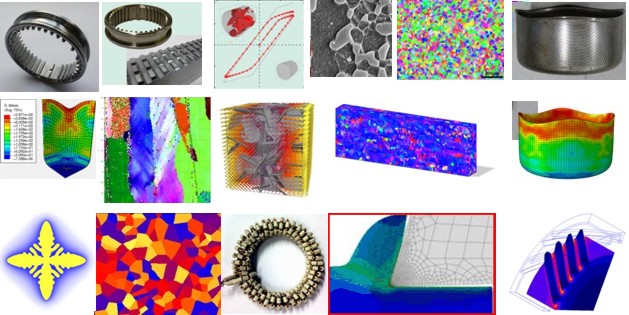

The importance of simulation for manufacturing engineering has risen over the past years. The vision of multi-scale and multi-process simulation promises major competitive advantages not only in factory and production planning, but also in product engineering. These advantages result from complex experimental studies for the identification of process parameters becoming redundant and from a significant reduction of product development times. Strategies for the simulation of single isolated manufacturing processes are already highly advanced and have been widely and successfully implemented. Before simulation-based production process development can become a reality, though, two crucial development steps are yet to be completed: It must be possible to

|