| Person in Charge: Dipl.-Ing. Valentina A. Pavlova |

|

Motivation:

- a lack of information on what exactly happens during the chip formation at the primary and secondary shear zones as well as effects which take place under different process conditions

- difficulty to get an insight into the process and the mechanical loading due to the high temperature gradients and high plastic strain rates in the machining process

Aim:

- development of an improved methodology for chip formation simulation under ABAQUS/Explicit

- analysis of the influence of process and material parameters on the process values and stability

| |

| Research |

Results |

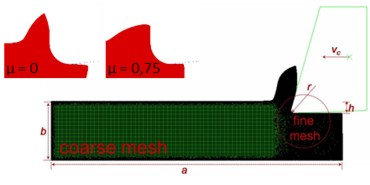

- modeling of the orthogonal metal cutting process

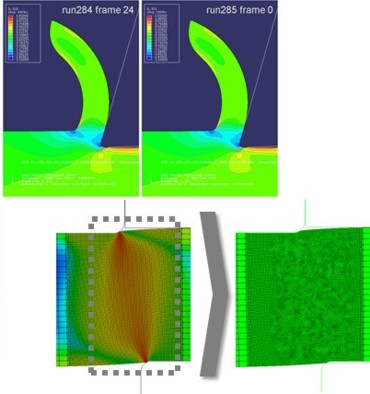

- development of remesh procedures

- comparison of simulations with the explicit and implicit solvers implemented in ABAQUS

- investigation of the influence of high friction coefficients by finite element simulations

- application of a new remesh method to the blanking process

|

|

|

| |