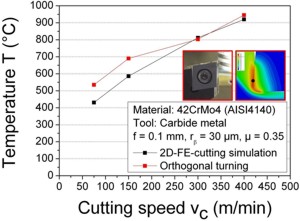

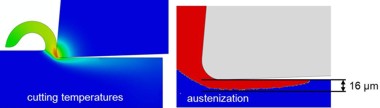

- 2D-FE cutting simulation with detailed modeling of friction, heat transfer and phase transformations for the steel 42CrMo4 (AISI4140)

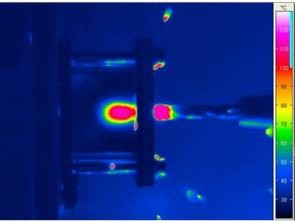

- Turning and drilling experiments with measurement of temperatures and forces

- Abstract modeling of the drilling process (3D-FE model)

- Simulation of phase transformations and work piece distortions

- Defining strategies of compensation

|

|

|

|

Thermal image of drilling experiment |

|

- 2D-FE model shows good agreement of calculated temperatures and forces in relation to the measured results of the turning experiments

- Austenization implemented in cutting simulation

- Friction coefficient decreases with increasing sliding speed and approaches towards a maximum at higher temperatures

|

| |