|

Motivation and objectives:

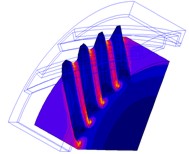

Induction surface hardening is an energy-efficient and low distortion alternative to case hardening.

In order to evolve its full potential, numerical process models are necessary. On one side they allow the identification of modes of action and on the other the developement of a much deeper process understanding. At the moment, there are no process modells for dual frequency induction surface hardening. Hence, the objective of this project focuses on developing a finite element process modell, while considering process specific aspects in order to predict residual stress distributions and distortion.

| |